ROBOTICS INTEGRATION

MADE EASY

When you partner with Hil-Man Automation, you get the advantage of expert support from our renowned customer service team. Read about the services we provide to our customers below.

Turnkey Automation

Are you looking to automate your process? We can build a system to maximize your productivity!

Turnkey automation refers to a complete, end-to-end solution that is ready to use and operate with minimal involvement from the customer. In the context of manufacturing and production processes, the process involves the design, implementation, and commissioning of a complete automation system that meets the customer’s specific requirements.

In today’s fast-paced business environment, labor and material shortages are becoming more frequent, making automation an absolute necessity. Automated systems can significantly increase the efficiency of production processes, reducing the time it takes to complete a task and minimizing the need for manual labor. It can also be easily adapted to changing production needs, making it possible for companies to respond quickly to market demands.

At Hil-Man Automation and Precision Dispense Technologies, we understand the challenges that come with automation and are here to help. We offer customized solutions that cater to unique needs and budget, and our in-house team has the expertise and resources to ensure the success of a new system. As a certified system integrator for FANUC robotic products, we have also developed strong partnerships with leading robotics companies. This allowed us to gain technical skills, trust, and knowledge in the industry.

Take advantage of our turnkey operation that features off-the-shelf specialized technologies and our software programming and integrated vision system capabilities. Automate your production process today and gain a competitive edge!

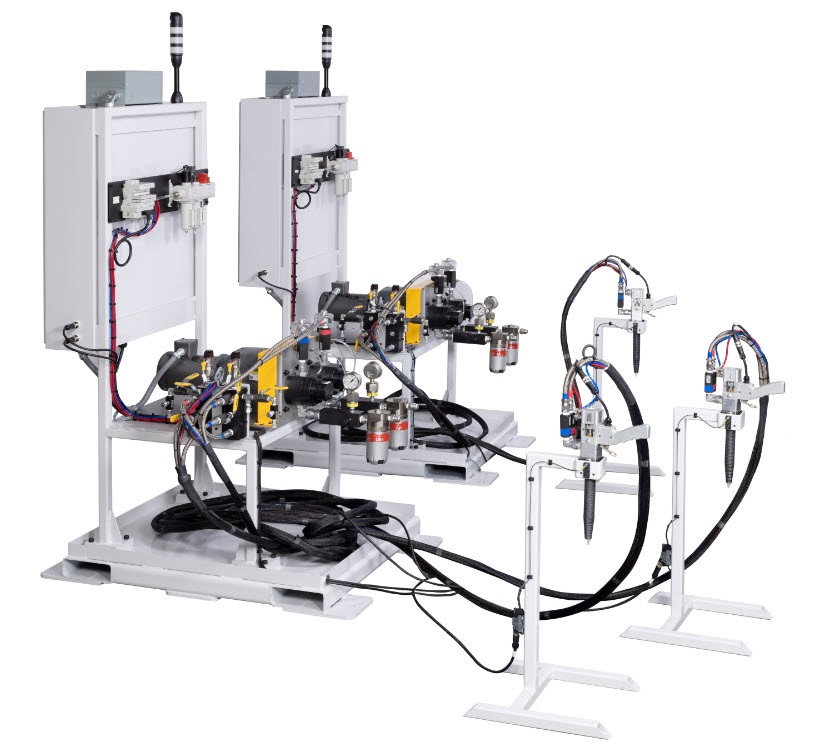

Custom Dispense Systems

Whatever your dispensing needs, we will design a system for your application!

All product-assembly mechanisms in the industrial and manufacturing industries necessitate using adhesive, appropriate dispensing equipment, and an effective quality improvement method. Adhesive dispensing systems perform two functions: applying adhesive and assembling components together.

Adopting custom dispense systems for adhesive applications is both innovative and efficient. However, the high cost of equipment, maintenance, and other associated expenses can make it a costly endeavor. So, if you are still determining which automated adhesive dispensing system to use, Hil-Man Automation and Precision Dispense Technologies can help you!

We design custom dispensing systems with high-quality adhesive applications using the most advanced robotic technology and the smartest, highest-quality equipment available today. As a result, we give our customers more control over the bonding process, help them save money, and boost their profitability.

Ready to Get Started?

Custom Automation Solutions

Whatever your dispensing needs…

We’ll design a system for your application.

Custom Automation Solutions

Whatever your dispensing needs…

We’ll design a system for your application.

Engineering & Prototyping

Are you looking to create something new? We will help you engineer and build it from scratch!

Engineering and prototyping play crucial roles in product development and innovation. They are the key stages of creating new products, ensuring that they are both functional and practical. The following are some of the reasons why engineering and prototyping are important:

Idea Validation

Product developers can test their ideas with engineering and prototyping to see if they are viable. This helps to avoid wasting resources and time developing products that do not meet customer needs or are inefficiently manufactured.

Problem Solving

A company that offers extensive engineering and prototyping services provides a platform for developers to identify and solve problems that may arise during the development process. This helps to ensure that the final product is of high quality and meets the intended specifications.

Iteration

Iteration is the process of making changes to a design and refining it. This enables developers to test and refine their designs in a controlled and cost-effective manner. By making changes and improvements to the product in small increments, they can ensure that the final product is of high quality. Moreover, this process can help to reduce costs by allowing them to identify and resolve issues before the final product is manufactured.

User Testing

User testing through prototyping is a critical step in the product development process. By allowing real people to test the product, product developers can gain valuable insights into how the product will be used and perceived by the target market. This information can then be used to make improvements before the product goes to market.

For businesses that require unique automation solutions with stringent quality requirements, Hil-Man Automation is the ideal partner. Our engineering team works closely with your production launch team to create a custom system that meets your unique needs and specifications.

At Hil-Man Automation, we are dedicated to finding innovative ways to enhance the efficiency of our customers’ production processes. Our expertise extends to designing and producing new dispensing products and modifying existing ones to fit your specific application. Whether you need a one-of-a-kind system, our team is here to help.

Preventative Maintenance

Let us take care of your equipment. We will keep it running at peak performance!

Preventative maintenance ensures optimal working conditions while extending any equipment’s life. This process may cause minor production delays, but these are insignificant compared to the downtime caused by a breakdown. At Hil-Man Automation, we can assist you in sustaining a preventive maintenance schedule to guarantee that your machine systems perform optimally!

Here are some of the benefits of regularly performing preventive maintenance on your machine systems:

Machine and Operator Safety

Regular preventive maintenance ensures that your machinery operates safely for the equipment and the operators. Potential problems can be identified and addressed before they cause harm.

Machine Efficiency

Abrasive wear and tear can deteriorate machine efficiency. Preventive maintenance preserves optimal working conditions while extending the life of the equipment.

Time Savings

Scheduled maintenance enables the production to develop the best time and account for the inconvenience. It is also faster than emergency repairs and replacements.

Customer Satisfaction

Preventive maintenance to avoid breakdowns and maintain the quality of goods guarantees customer satisfaction and strengthens the brand image.

Preventative Maintenance

Let us take care of your equipment…

We’ll keep it running at peak performance.

Preventative Maintenance

Let us take care of your equipment…

We’ll keep it running at peak performance.

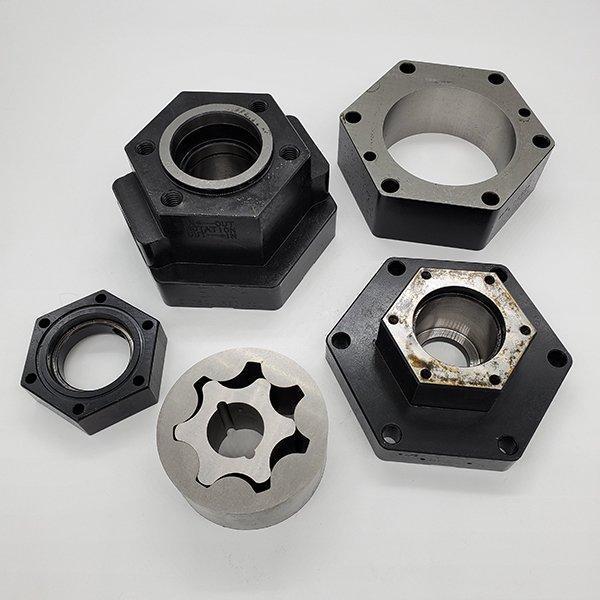

Refurbishing & Testing

Send us your old broken equipment, and we will return it to you in working order!

Refurbishing is the process of restoring used or outdated equipment to its original or near-original condition, often for reuse or resale. It is an essential aspect of modern-day operations, offering cost savings, sustainability, improved efficiency, reliability, and accessibility. In addition, by adopting a refurbishment strategy, you can maintain and improve your operations while reducing your business’ environmental impact.

Hil-Man Automation provides comprehensive refurbishment services for its dispensing systems, guns, and pumps. Our process begins with a thorough inspection and disassembly of the equipment to assess for any damage. Once cleared, individual parts are cleaned and reconstructed with all necessary components, bringing them back to optimal functioning.

To guarantee quality, all refurbished dispense guns and pumps undergo rigorous testing to meet the same standards as when they were first manufactured at our facility.

Partner With Hil-Man Automation for Your Precision Dispensing Needs!

We at Hil-Man Automation and Precision Dispense Technologies have the dedication, adaptability, and creativity to provide you with turnkey program solutions from concept to completion! Our experienced engineering and manufacturing teams have designed and built complex specialized machines, work cells, and simple automated fixtures. We can also come to your facility if you want a more hands-on assessment and evaluation.

Contact us or request a quote for your adhesive application requirements today!