Robotic Soldering

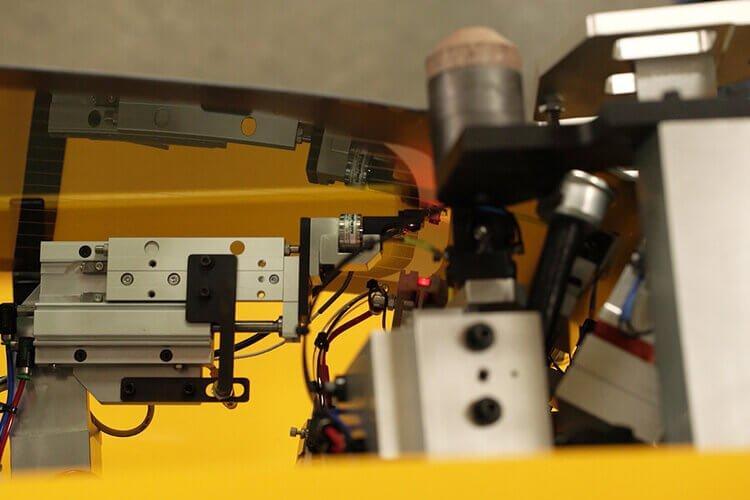

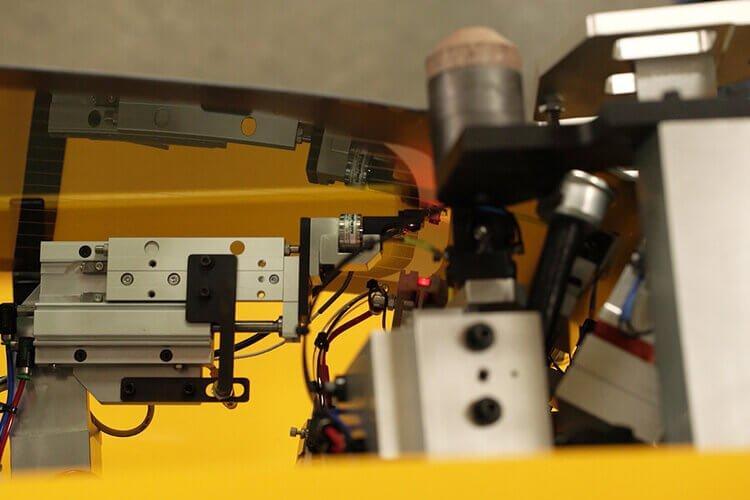

Our robotic soldering system creates precision and repeatability in your soldering process–and can even test for connection, attach other components, and much more.

You can count on our expert engineering and manufacturing teams to create a seamless integration with your current equipment.

Robotic Soldering

Our robotic soldering system creates precision and repeatability in your soldering process–and can even test for connection, attach other components, and much more.

You can count on our expert engineering and manufacturing teams to create a seamless integration with your current equipment.

Save costs and increase ROI with a robust, versatile, self-verifying robotic soldering system from Hil-Man Automation.

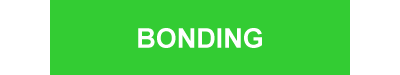

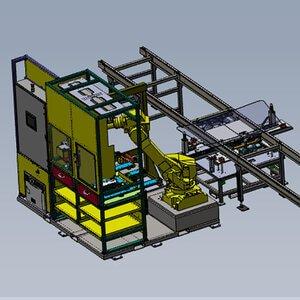

With leading automation technology, vision systems, and smart design, Hil-Man Automation has developed a robotic soldering system that can check and track proper functioning, and execute any number of additional assembly operations–reducing your operating costs and increasing return on investment.

Hil-Man Automation engineers know the key to a robust robotic soldering system is its accuracy, versatility, and speed. Our custom-tailored systems perform multiple tasks in record time for a multitude of tasks on a production line. We design systems that are custom-tailored. Every detail of your assembly process is carefully analyzed and calibrated to meet your specs to ensure accuracy and quality execution.

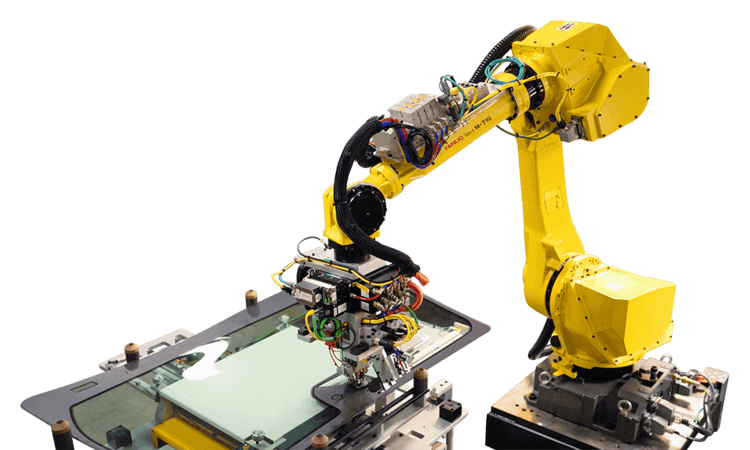

Get a perfect solder every time and minimize overall assembly time and costs.

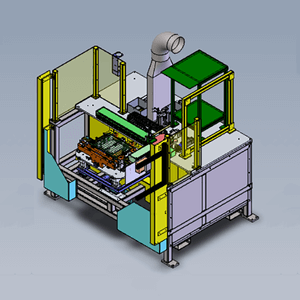

With an automated soldering assembly fixture, your operator can have all of your required locator pins and spacers attached to the windshield, and have thirteen electrical components soldered and tested for proper functioning–all done in 22 seconds or less.

Get a perfect solder every time and minimize overall assembly time and costs.

With an automated soldering assembly fixture, your operator can have all of your required locator pins and spacers attached to the windshield, and have thirteen electrical components soldered and tested for proper functioning–all done in 22 seconds or less.

A turnkey robotic soldering system that hits the spot every time.

We know we’re doing it right when our customers spec our work, which happens a lot. Trust our expert team and committed support staff to design and build your robotic soldering system!

Want to see our robotic soldering capabilities in action?

Here are a few examples–click the drawings below for photos and descriptions of each project.

How can we help you?

We have the expertise, experience and capacity to deliver your primer application equipment–on time.

How can we help you?

We have the expertise, experience and capacity to deliver your primer application equipment–on time.

Not sure what you need yet?

Our engineering sales and design team can talk you through every option and specification for your primer application equipment. Hil-Man experts are available to visit your facility to assess your current production line to ensure a seamless integration.

We also offer full servicing, refurbishing, and upgrading on existing systems to help you improve speed and accuracy with minimal investment.