Robotic Encapsulation

Make your molding process faster, and more precise and repeatable by integrating one of our robotic encapsulation systems.

Our expert engineering and manufacturing teams will design and build a system that fulfills all of your molding requirements.

Robotic Encapsulation

Make your molding process faster, and more precise and repeatable by integrating one of our robotic encapsulation systems.

Our expert engineering and manufacturing teams will design and build a system that fulfills all of your molding requirements.

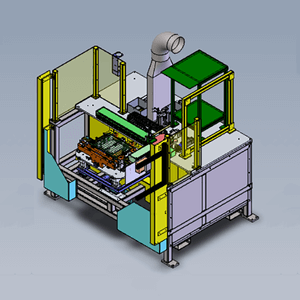

Achieve the precision, versatility, and repeatability needed to meet your customer’s glass manufacturing requirements.

As the functionality and design of automotive windows become more and more complex with the latest driver-assist systems and vanity features, count on Hil-Man Automation’s expert team to deliver a complete robotic encapsulation system and robot framework capable of meeting demands–while increasing productivity and reducing costs.

When it comes to robotic encapsulation, you need the expertise of engineering and automation experts to streamline your process. Hil-Man Automation has years of experience delivering turnkey encapsulation systems tailored to our customers’ needs. We are known for innovative solutions that make production lines more efficient and profitable.

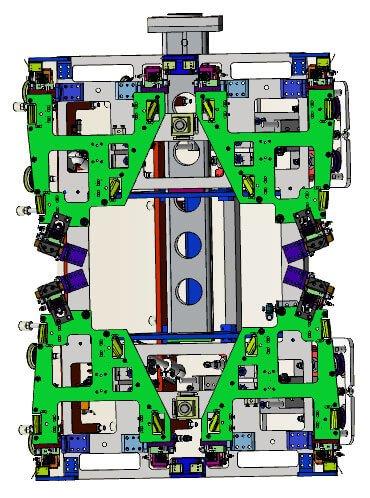

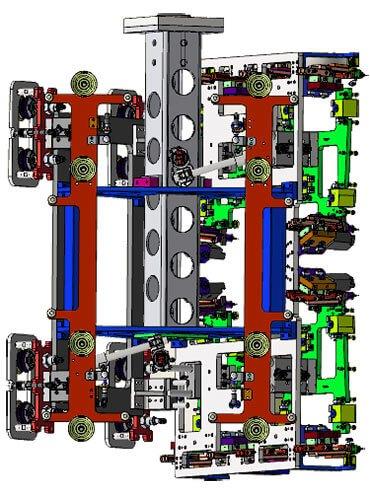

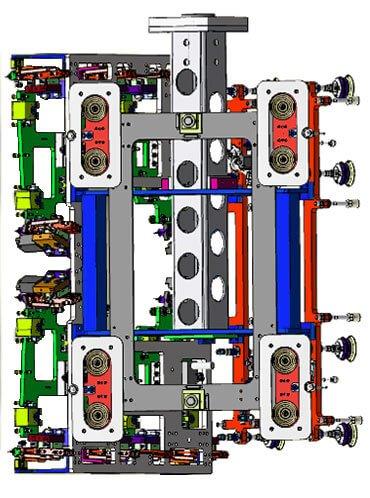

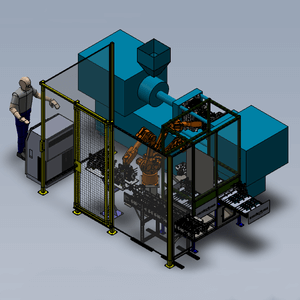

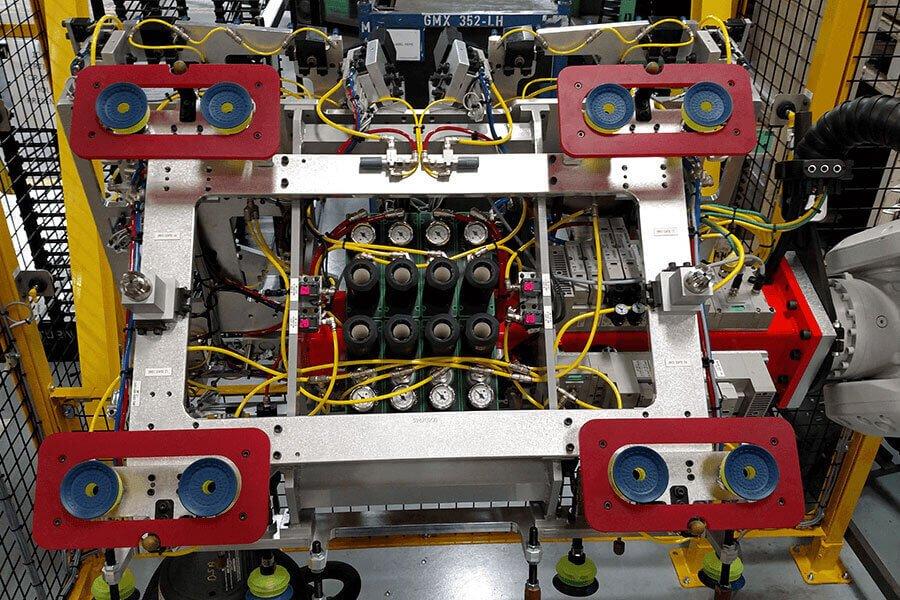

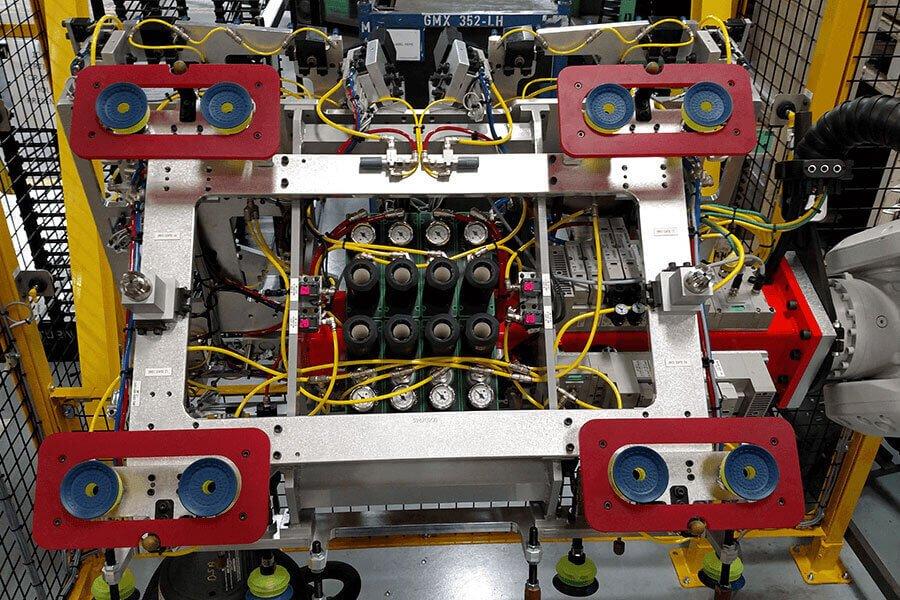

One end of arm tool: countless capabilities.

People are often stunned when they see how many steps of the encapsulation process we can execute with one robot. With this 3-sided end of arm tool (EAOT), one robot can pick and place 4 pieces of glass along with 4 sets of bezels and locating pins into your mold machine, pick up more parts while it works, and then pull the assembled automotive glass out of the mold and move it to a conveyor.

One end of arm tool: countless capabilities.

People are often stunned when they see how many steps of the encapsulation process we can execute with one robot. With this 3-sided end of arm tool (EAOT), one robot can pick and place 4 pieces of glass along with 4 sets of bezels and locating pins into your mold machine, pick up more parts while it works, and then pull the assembled automotive glass out of the mold and move it to a conveyor.

If you’re looking for a manufacturing automation supplier that thinks outside the box and has the experience and expertise to tackle any challenge, you are in the right place.

The engineering and manufacturing teams at Hil-Man Automation have what it takes to deliver a turnkey robotic encapsulation system, custom-designed to meet your goals, and strong enough to withstand daily use and abuse.

We know we’re doing it right when our customers spec our work, which happens a lot. Trust our expert team and committed support staff to design and build your robotic encapsulation system.

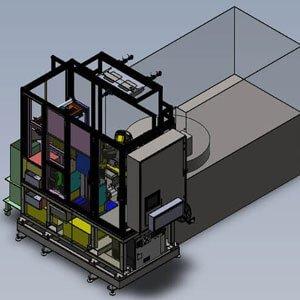

Want to see our mold tending and encapsulation systems in action?

Click the drawings below for photos and descriptions of some of the robotic encapsulation systems we have delivered.

How can we help you?

We have the expertise, experience and capacity to deliver your primer application equipment–on time.

How can we help you?

We have the expertise, experience and capacity to deliver your primer application equipment–on time.

Not sure what you need yet?

Our engineering sales and design team can talk you through every option and specification for your primer application equipment. Hil-Man experts are available to visit your facility to assess your current production line to ensure a seamless integration.

We also offer full servicing, refurbishing, and upgrading on existing systems to help you improve speed and accuracy with minimal investment.