FOR IMMEDIATE RELEASE

Hil-Man Automation Celebrates the One Year Anniversary of Launching its New Subsidiary Precision Dispense Technologies (“PDT”) with a Socially Distanced Party and Equipment Demonstrations

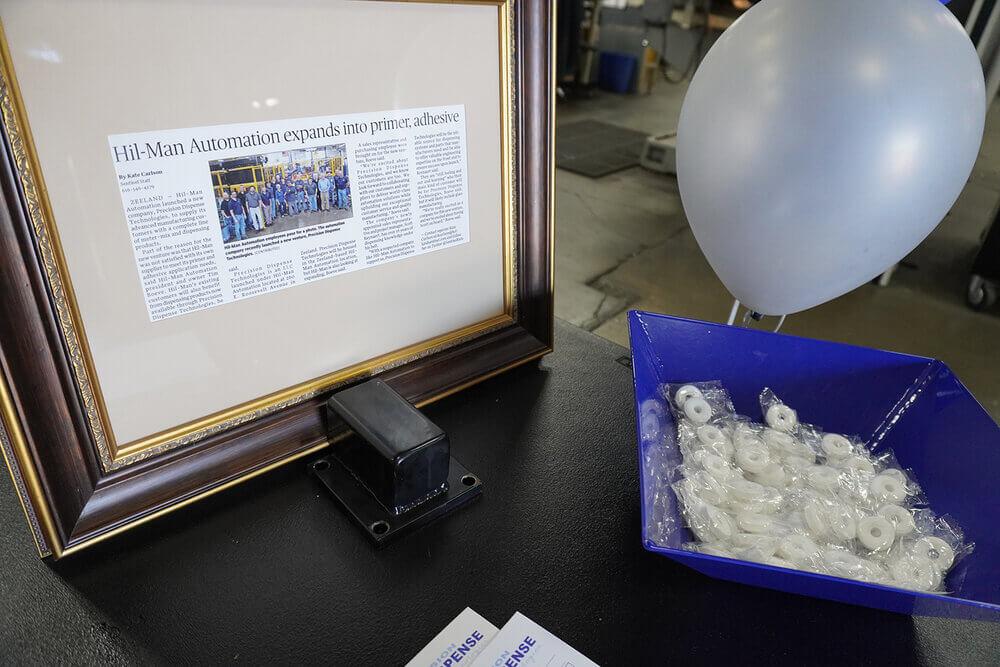

ZEELAND, Mich., June 23, 2020 — Last week, Hil-Man Automation invited a few guests to join them for a socially distanced celebration honoring the one year anniversary of the company’s new subsidiary, Precision Dispense Technologies, or “PDT” for short. Owner and president, Tim Boeve, was eager to commemorate his team’s success as a way of uplifting his community in the wake of the quarantine, ensuring the safety of guests and team members.

Arriving in fabric masks and keeping six feet apart, Jane Clark, President of the West Coast Chamber, Greg King, Business Solutions Manager at Lakeshore Advantage, and Jeff Stutler, CPA at Geenen & Kolean listened intently as Boeve welcomed them, introduced himself, and gave a brief account of Hil-Man Automation’s history. He was proud to announce that his companies fared well through the shutdown, and have even continued to grow, hiring 3 new employees since Michigan’s governor gave the ok to reopen manufacturing.

The decision to launch PDT, he explained, was made back in the Spring of 2019 in order to address vast unmet demand for meter-mix and dispensing parts left by the sudden closure of Hil-Man’s former supplier, EMC Squared of Auburn Hills. Securing the expertise and sales talents of 16-year EMC Squared veteran, Scott Reynaert, Hil-Man was able to quickly get to work doing what it does best: solving problems for customers.

“We have a great team that works hard to keep Hil-Man and PDT at the cutting edge of automation equipment and to ensure that our custom systems deliver the best possible outcomes for our customers at the right value. Our success stems from our commitment to providing quality products and personal service to our customers,” Boeve said in closing. Inviting Reynaert to take the floor, the two men unveiled PDT’s first two comprehensive dispensing systems, set to ship later this month.

Before diving into a high-level explanation of the systems on display, Reynaert began by thanking his boss and the Hil-Man Automation team for starting PDT, for trusting him to grow the business, and for welcoming him like family. With a big smile, he added, “it’s been a great experience, and the nice thing is, we were able to help all my old customers.” One such customer in the automotive glass manufacturing arena ordered the two dispensing systems on display.

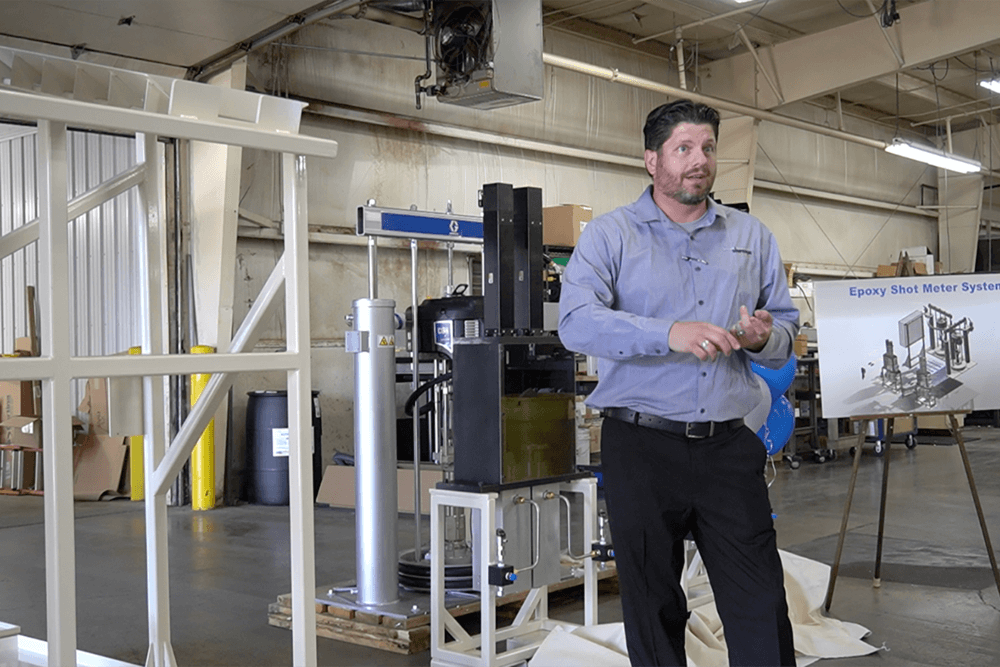

The first dispensing system will be part of a new production line for the a new electric delivery vehicle being purchased en masse by some of the big e-commerce players–a gravity feed system with two 55 gallon barrels on top, separately holding the two reactive parts of a structural adhesive solution by Ashland. As gravity works to empty the materials into a temperature-controlled reservoir system, keeping them around 78 degrees, a PDT-designed and constructed geroter pump draws a fixed amount of the two materials, delivering to a robot that has been outfitted with a PDT dispensing gun. The gun mixes the two parts internally as the robot applies a precise amount of the final adhesive solution to a raw glass window in the exact locations where components will be attached.

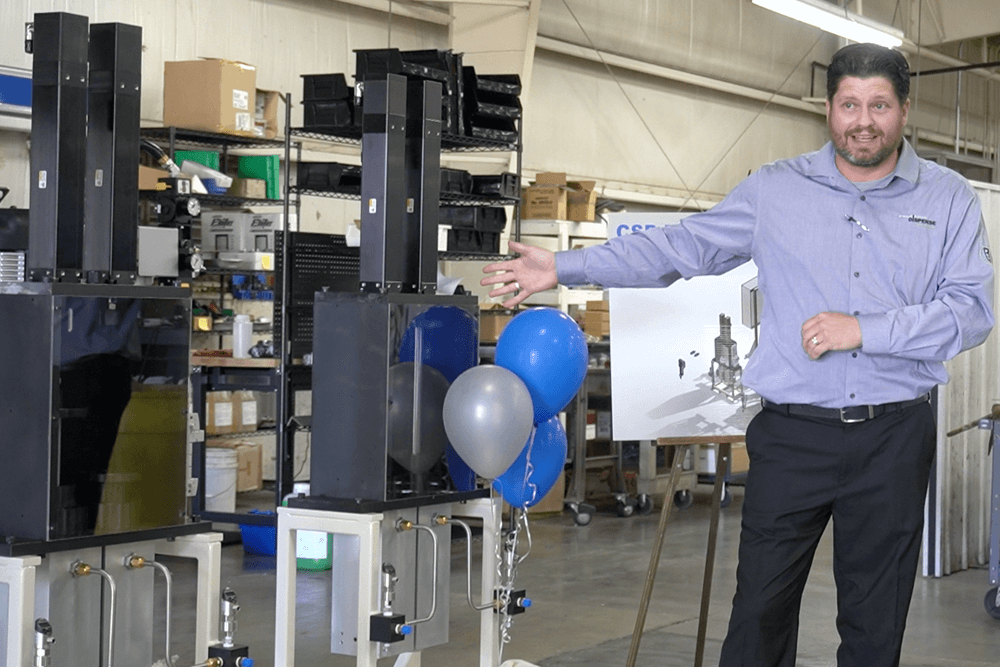

The second PDT system, Reynaert explained, is an epoxy system for a popular US-made small pickup truck. Designed and built to handle a much thicker adhesive material–think peanut butter consistency–this system also features two 55 gallon tanks holding two parts of an epoxy solution. However, instead of gravity pulling the materials down, this system has to apply more force to move the thick epoxy through to the dispensing guns by using a servo-driven linear actuator.

After a brief overview of the other systems Hil-Man had on the floor, which included a dual robot automotive glass priming and inspection cell and a heated conveyor system, guests said their goodbyes and were sent home loaded up with PDT-branded cupcakes in individual boxes by Holland Cakery.

Emily Wilkins, owner of Marketing Metal, was also present capturing photos (below) and reporting on the event.

About Hil-Man Automation

Headquartered in the growing automation hub of Zeeland, Michigan, Hil-Man has been providing turn-key, custom automation solutions to advanced manufacturers since 2003.

For more information, visit https://hil-manautomation.com/.

Media Contact: Julie Blakely

Julie.blakely@hil-manautomation.com

About Precision Dispense Technologies

Precision Dispense Technologies serves advanced manufacturers with high quality automated dispensing systems for adhesives and primers.

For more information, visit https://www.precision-dispense.com/.

Media Contact: Scott Reynaert

About Hil-Man Automation

Headquartered in the growing automation hub of Zeeland, MI, Hil-Man has been providing turn-key, custom automation solutions to advanced manufacturers since 2003.

For more information, visit https://hil-manautomation.com/.

Media Contact: Julie Blakely

Julie.blakely@hil-manautomation.com

About Precision Dispense Technologies

Precision Dispense Technologies serves advanced manufacturers with high quality automated dispensing systems for adhesives and primers.

For more information, visit https://www.precision-dispense.com/.

Media Contact: Scott Reynaert