Automation Equipment Specialties

Check out some of our custom automated equipment and solutions that help our customer do more with less.

Scroll down to see examples of our work.

Automation Equipment Specialties

Check out some of our custom automated equipment and solutions that help our customer do more with less.

Scroll down to see examples of our work.

Our Automation Specialties

Hil-Man Automation engineers design systems that are tailor-made to your applications, ensuring your satisfaction. Our customized systems run the gamut to meet the needs of every type of production line. Every component is made to your specs using the most advanced robotic technology which offsets capital costs and boosts profitability.

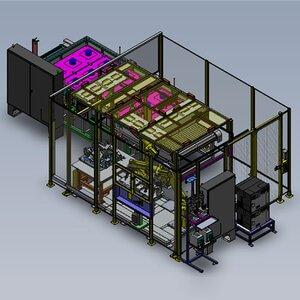

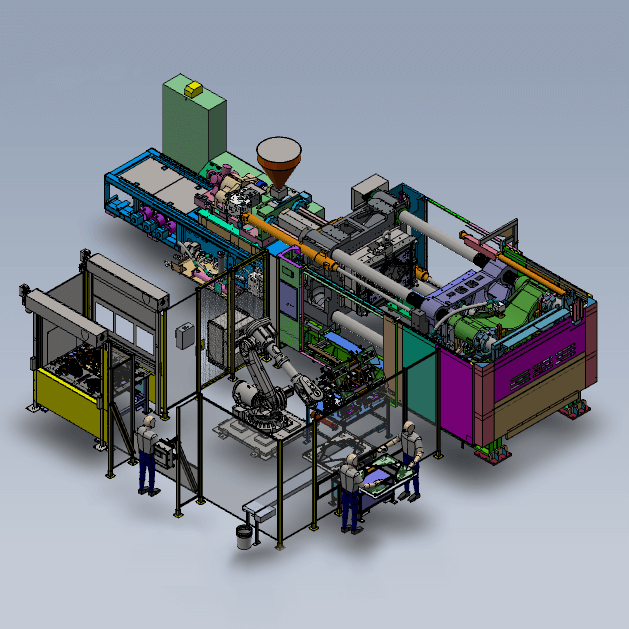

Primer Application Systems

Save floor space and capital by integrating the Hil-Man Automation universal robotic primer application system.

Using the latest robotic technology paired with cutting-edge vision systems, Hil-Man Automation has the expertise in designing and building universal robotic primer application cells that can run unlimited glass styles without changeover–saving you labor and capital equipment costs.

Browse our Primer Application Case Studies:

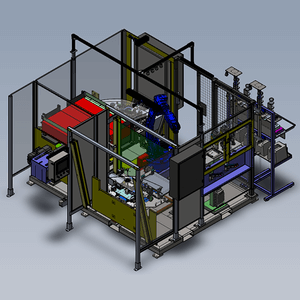

Adhesive Application Systems

Save labor costs and boost profitability with a turnkey robotic adhesive application system from Hil-Man Automation.

Using the latest robotic technology paired with a carefully designed and calibrated adhesive dispensing system, Hil-Man delivers a turnkey robotic adhesive application cell that not only provides more control over your bonding process but also saves costs and increases profits.

Browse our Adhesive Application System Case Studies:

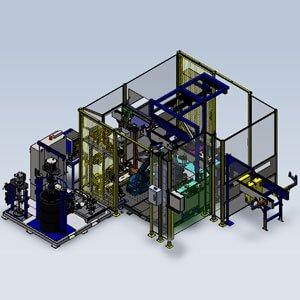

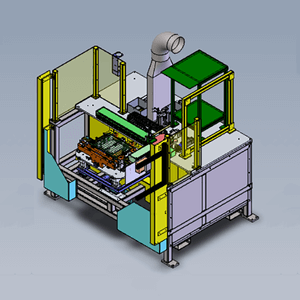

Automated Soldering Systems

Save costs and increase ROI with a robust, versatile, self-verifying robotic soldering system.

With leading automation technology, vision systems, and smart design, Hil-Man Automation has developed a robotic soldering system that can check and track proper functioning, and execute any number of additional assembly operations–reducing your operating costs and increasing return on investment.

Browse our Automated Soldering System Case Studies:

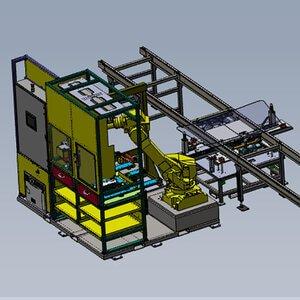

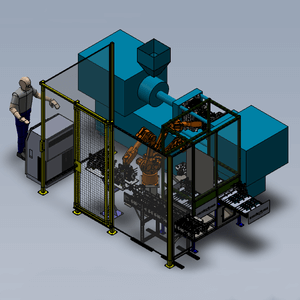

Mold Tending and Encapsulation Systems

Achieve the precision, versatility, and repeatability needed to meet your customer’s molding or encapsulation requirements with Hil-Man Automation.

As skilled manual labor becomes more and more difficult to come by and the cost of manufacturing continues to go up, count on Hil-Man Automation’s expert team to deliver a complete encapsulation or press tending system to increase productivity and reduce overhead.

Browse our Mold Tending and Encapsulation Case Studies:

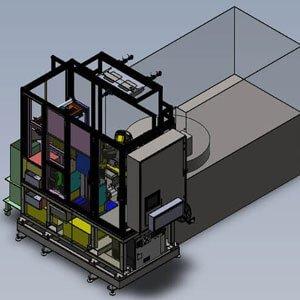

Assembly Fixtures & Workstations

Reduce assembly times and improve working conditions with a custom automated workstation or fixture from Hil-Man Automation

The innovative team at Hil-Man Automation has helped customers achieve staggering feats with one smartly designed workstation or fixture. By staying ahead of technology and thinking outside the box, our robotics company often surprises customers with the sheer number of processes we can design into one inexpensive unit.

Browse our Assembly Fixtures & Workstation Case Studies: