Automotive & Aerospace

As our customers’ needs change, we’re always looking for new ways to meet them.

Our Specialties

Subhead

Over the course of more than 26 years, we have built automotive systems and manufactured a variety of automotive parts and components.

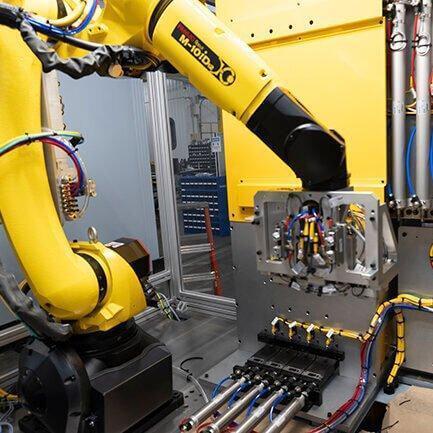

Manufacturing, welding, assembly, and material handling processes in the automotive industry can all benefit from automated equipment. Automating usually involves integrating robotics into key areas to save time, increase capacity, and protect employees from dangerous conditions and repetitive labor. Welders, assemblers, inspectors, and testers of car parts and original equipment manufacturers (OEMs) use robotics and vision technology. Automation has recently increased in flexibility and sophistication. There are still many more opportunities to integrate automation to optimize car manufacturing processes.

Our Capabilities

Our team has built custom technology solutions for every application, process, and industry—from assembly automation, dispensing, and vision systems to process design, controls engineering, and software integrations.

Our Capabilities

Our team has built custom technology solutions for every application, process, and industry—from assembly automation, dispensing, and vision systems to process design, controls engineering, and software integrations.

Turnkey Models

Subhead

Fully customized solutions aren’t always the best option. We can engineer our standard platforms to fit your parts or processes.

Applications Of Automotive Automation

Automotive companies and their automation partners design and deploy robots in high-speed, high-throughput areas to complete welding, inspection, material handling, and assembly of all sorts of parts from under the hood to the cabin. For example, robots have been a crucial part in producing fuel systems, engines, electronics, lights, mirrors, auto body components, and more. Automotive robots are getting faster, smarter, and more efficient.

Assembly Systems

Automation can be deployed in automotive assembly lines for riveting, fastening, or snapping together parts big and small. Pairing robotics and vision is ideal for optimizing product assembly lines. Companies have successfully optimized their lines for glass installation and urethane application, assembly component bonding, and material handling parts. The benefits include reducing labor costs, reaching new throughput goals, and increasing quality.