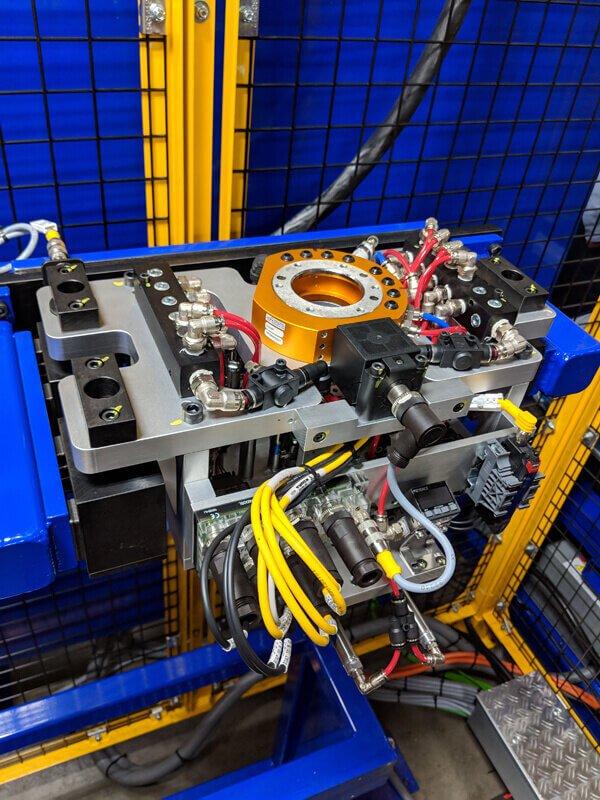

Windshield Priming Bonding Assembly Cell

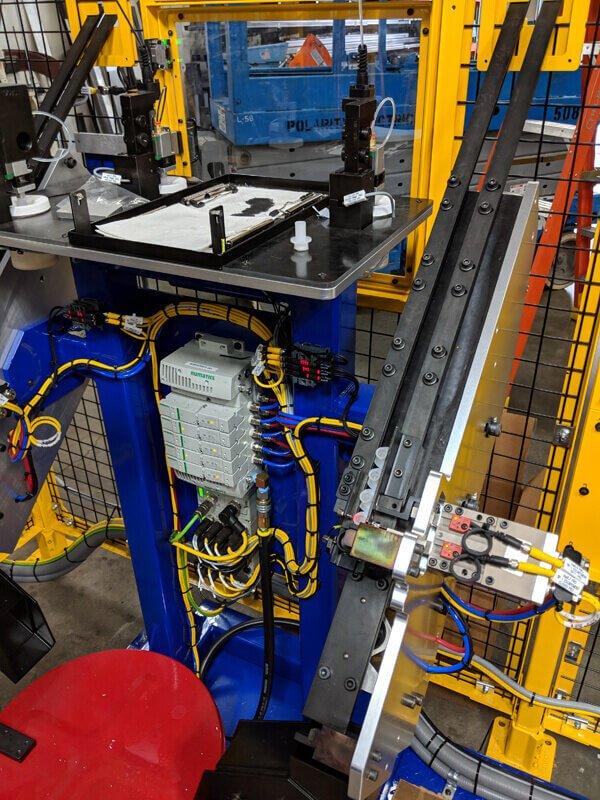

This system integrates robots and manual labor to perform several tasks on an almost infinite range of automotive windshield models. For the priming and bonding, instead of crowding the glass, we strictly use the vision system to tell the robots where the glass is, and then the robots will go to where the vision system directs them to go.

- The forklift will load raw glass racks into two loading bays where the robot will then take the raw glass individually from the racks.

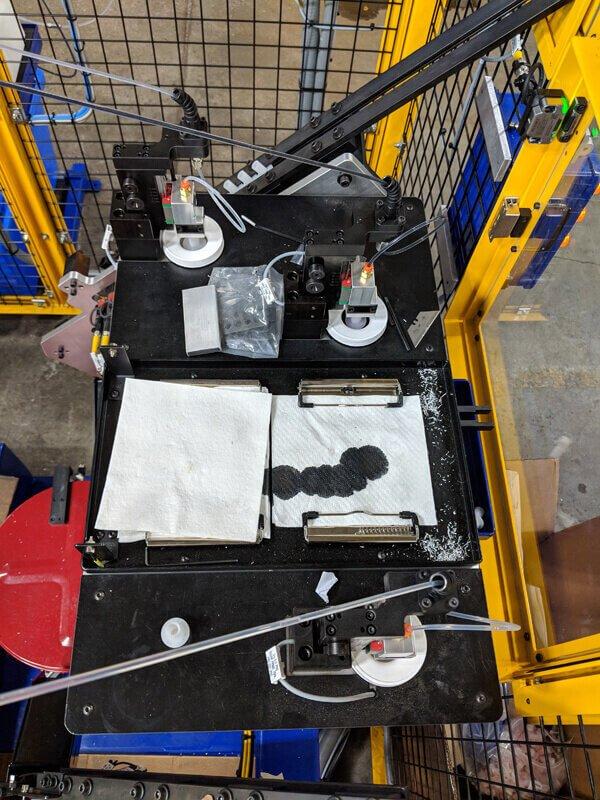

- Robot 1 takes the raw glass, presents it to a bar code reader for part verification, swipes the glass spacers off onto an unload conveyor, cleans the window with IPA, and then loads the glass onto the conveyor.

- This cell can also be manually loaded if need be.

- Robot 2 is the priming robot. The robot applies the following primers in under one minute:

- Clear Primer

- Black Primer

- UV Primer for the elkamet and seal apply.

- The primer cures on the next 8 stations on the conveyor.

- There is an operator station in the middle of the conveyor, where the operator performs tasks such as:

- Manually inspects primer

- Applies a Barcode Sticker

- Applies 4 spacers.

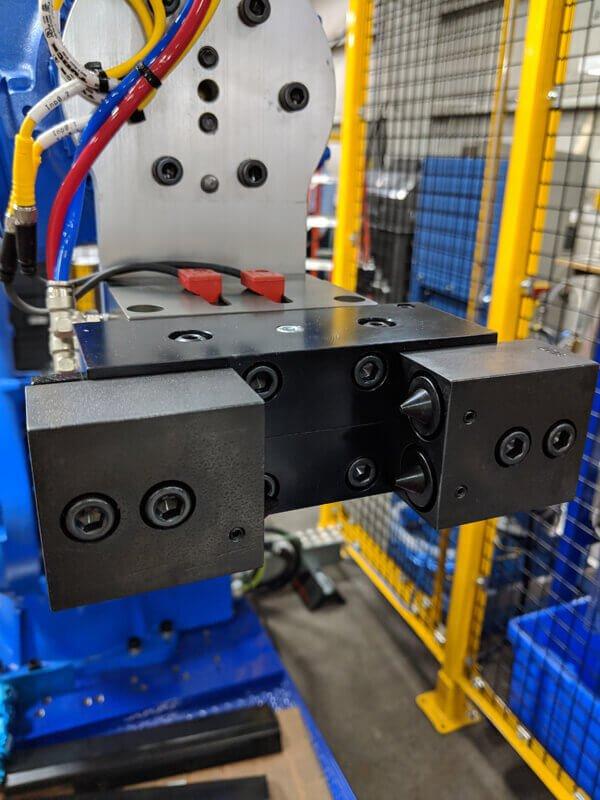

- Robot 3 picks the camera brackets from the loading dial, applies urethane and hot melt, and then places the prepped bracket onto the window.

- Robot 4 would move the glass from the bonding station onto the elkamet apply station conveyor.

- Robot 5 moves the glass from the elkamet apply station, to the seal apply station, and then to the unload conveyor.