Rear Slider Priming Bonding Assembly Cell

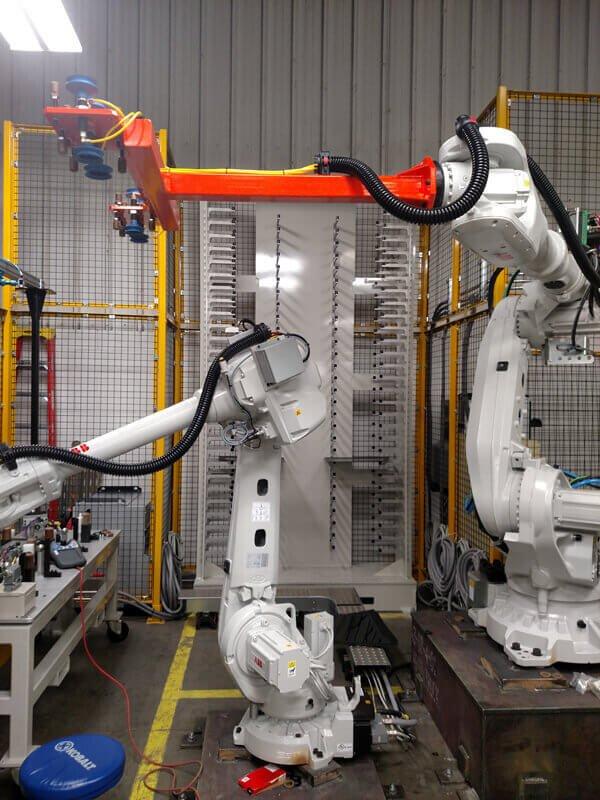

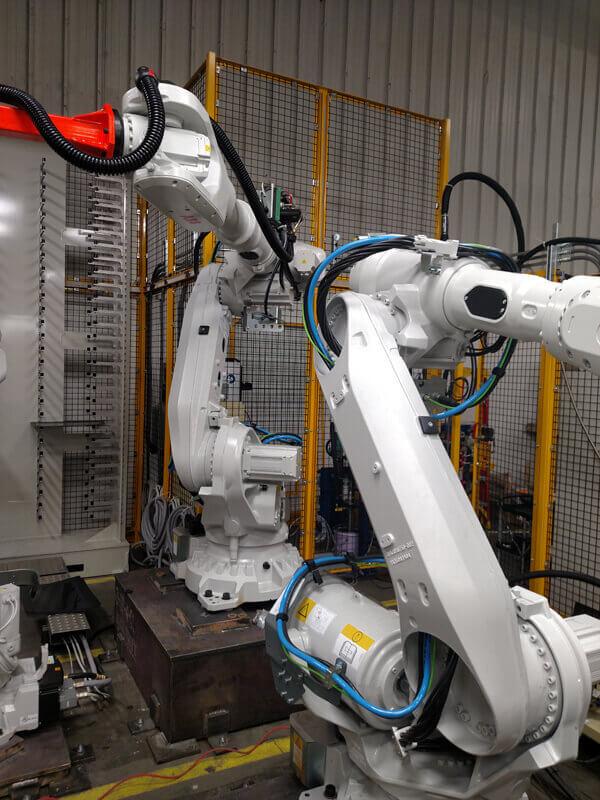

A conveyor (or operator) feeds the raw glass to a material handling robot, which picks it up and puts it into a priming station (shown on the left hand side) where another robot applies primer. From there, the material handling robot places it in a rack to allow the primer to cure, and then takes the glass to a bonding station (right hand side).

Due to high volumes and quick cycle times, we designed this cell with two bonding stations. The operator loads the components needed for the final product while the dispensing robot applies glue in preparation for the material handling robot to load the glass into the fixture to complete the assembly.

This work cell also has a 10-camera vision system for parts inspection, and features a PDT Precision Dispense System with automatic tip-changing for primer application.