Automation has become a big part of various industries as it significantly contributes to increasing capacity and productivity. Today, only less than half of manufacturing hours rely on manual labor, and we have automation to thank for that. Robotic adhesive dispensing is one example of automation being put to good use. An automated adhesive dispensing system saves workers from the tedious task of repetitively applying glue to one part and then bonding it with another.

What Are Automated Adhesive Dispensing Systems?

Automated adhesive dispensing systems utilize robotic equipment to release adhesive products evenly and efficiently. This process dispenses the exact amount of adhesive or sealant each time to reduce waste and create excellent and consistent final products. Because of the efficiency and accuracy of automated adhesive dispensing systems, it is preferred for applications that include assembly processes, such as window, windscreen, and bodywork gluing.

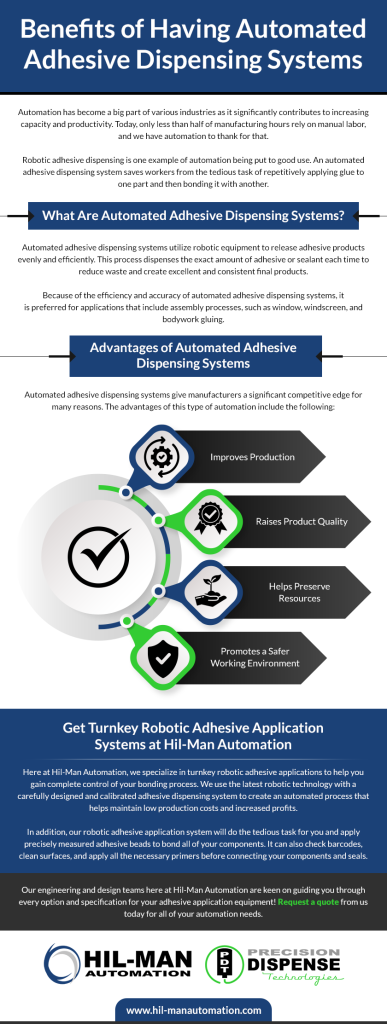

Advantages of Automated Adhesive Dispensing Systems

Automated adhesive dispensing systems give manufacturers a significant competitive edge for many reasons. The advantages of this type of automation include the following:

Improves Production

Having automated adhesive dispensing systems in a workplace can massively improve production. These systems help expedite manufacturing processes by applying adhesives faster and with high precision and repetition. Automated systems are also easy to use; this means operators can manage the robotic equipment for longer periods, helping the company meet and exceed clients’ demands effectively.

Raises Product Quality

Thanks to the consistency and accuracy of automated adhesive dispensing systems, manufacturers can raise the quality of their products. These automation systems ensure that outputs follow strict guidelines and design standards. In addition, increasing product quality through automated adhesive dispensing also mitigates the number of products discarded for having defects caused by inaccurate gluing.

Helps Preserve Resources

Automated adhesive dispensing systems help preserve resources by minimizing wasted materials used during production. The equipment can also be operated manually to conserve power while retaining speed and accuracy.

Promotes a Safer Working Environment

Automated adhesive dispensing systems help protect workers from types of adhesive that pose health risks. Because this automation equipment takes care of almost everything, workers don’t have to strain themselves from handling a glue dispenser or risk suffering adverse reactions from heavy-duty adhesives.

Get Turnkey Robotic Adhesive Application Systems at Hil-Man Automation

Here at Hil-Man Automation, we specialize in turnkey robotic adhesive applications to help you gain complete control of your bonding process. We use the latest robotic technology with a carefully designed and calibrated adhesive dispensing system to create an automated process that helps maintain low production costs and increased profits. In addition, our robotic adhesive application system will do the tedious task for you and apply precisely measured adhesive beads to bond all of your components. It can also check barcodes, clean surfaces, and apply all the necessary primers before connecting your components and seals. Our engineering and design teams here at Hil-Man Automation are keen on guiding you through every option and specification for your adhesive application equipment! Request a quote from us today for all of your automation needs.